NEW TECHNOLOGIES FOR ENHANCED ENVIRONMENTAL TESTING ON SPACECRAFT STRUCTURES

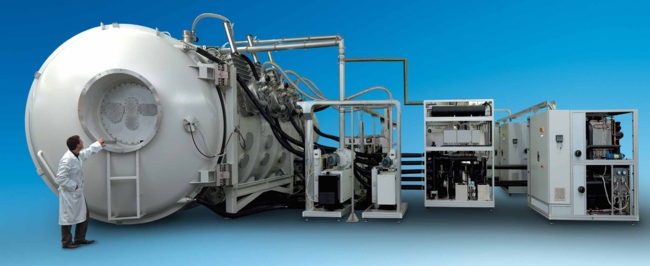

Test equipment for propulsion systems

The purpose of this application is a continuous testing of a Hall thruster during operation, at pressures lower than 1x10-5 mbar. During the simulation the thruster emits high-energy ionized gas in form of plasma, which implies two significant problem for the environmental simulation carried out in a TVC: Emerging gases and their high temperature

The purpose of this application is a continuous testing of a Hall thruster during operation, at pressures lower than 1x10-5 mbar. During the simulation the thruster emits high-energy ionized gas in form of plasma, which implies two significant problem for the environmental simulation carried out in a TVC: Emerging gases and their high temperature

Our engineering solution comprises inter alia, a pumping system compatible with the layout of the whole system and capable to remove produced gases from the TVC while maintaining high vacuum conditions and a temperature control system that is able to couteract the effects of high-temperature plasma.

Testing for next exploration voyage to Mercury

Testing for next exploration voyage to Mercury

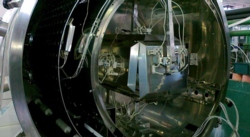

This system is designed to simulate environmental conditions of a space vehicle during the next exploration voyage to Mercury, in order to verify the behaviour of antenna receiver materials.

The particular requirement towards the testing system is to increase and maintain the surface temperature of a specific DUT up to +550°C under high vacuum conditions.

For this purpuse we have developed, manufactured and tested a special device, which is capable to generate thermal energy and control its power in accordance to the set temperature on the specimen, while being place inside a common TVC during the reproduction of aerospace conditions.

For this purpuse we have developed, manufactured and tested a special device, which is capable to generate thermal energy and control its power in accordance to the set temperature on the specimen, while being place inside a common TVC during the reproduction of aerospace conditions.

Outgassing phenomena and radiation of the black painted thermal shroud, caused by high temperature applications, were considered in the design and limited below the standard parameters in use for applications.

Solar simulation system inside TVC - a new approach

Solar simulation system inside TVC - a new approach

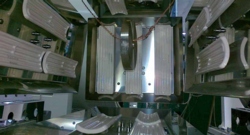

This new approach was developed for an existing TVC in the course of a complete system modernisation. The installation of a standard solar simulation system, consisting of water cooled xenon lamps outside the chamber and collimating mirror system inside the TVC, was not possible due to specific customer requirements.

For this purpose we developed a solar radiation system of max. 1400 W/m2 light intensity, consisting of 40 HMI lamps and completely erected inside the TVC.

The problem of optical speciment contamination in case of possible bulb explosion was resolved by integrating every lamp bulb in its own vacuum thight reflector box, provided with a forced air cooling system. As a consequence, the collimation angle and irradiation uniformity have increased comparing to standard system, but they could be minimised by the optimisation of the reflector geometry.

The problem of optical speciment contamination in case of possible bulb explosion was resolved by integrating every lamp bulb in its own vacuum thight reflector box, provided with a forced air cooling system. As a consequence, the collimation angle and irradiation uniformity have increased comparing to standard system, but they could be minimised by the optimisation of the reflector geometry.