CALORIMETERS

Application overview

Today environmental air conditioning has become a mass commodity: the presence of an air conditioner in a home or car, something that was rather rare up until a few decades ago, has now become commonplace.

Today environmental air conditioning has become a mass commodity: the presence of an air conditioner in a home or car, something that was rather rare up until a few decades ago, has now become commonplace.

The current situation, especially during the summer, determines consumption levels that account for a significant percentage of the national electricity requirements. What is more, it must not be forgotten that the use of domestic air conditioners is mainly concentrated during the daytime hours, when the demand for electricity reaches the highest levels, exacerbating the problems associated with peak demands.

From this perspective, and considering the ever-growing focus on rational uses of energy, it becomes of fundamental importance to maximize the energy efficiency of air conditioners, making them generate the desired coolness with the lowest possible electricity consumption.

Since the performance of an air conditioner is highly dependent on the temperature and humidity values of both the conditioned and the external environments, the climatic chamber is an irreplaceable simulation instrument.

Since the performance of an air conditioner is highly dependent on the temperature and humidity values of both the conditioned and the external environments, the climatic chamber is an irreplaceable simulation instrument.

Standard calorimeters for domestic air conditioners

Automobile air conditioners are highly customized on the basis of the vehicle in which they will be installed. This is true for both the geometries used and the cooling capacities delivered. On the other hand, domestic air conditioners, even though there are numerous manufacturers on the market, share many of the same elements in their construction solutions and performances.

For domestic air conditioners, specific standards of reference are in use in all industrialized countries, establishing how they are to be tested and permitting a clear-cut classification on the basis of both their functioning parameters and their energy efficiency.

As a result, Angelantoni Test Technologies has decided to develop a line of standard calorimeters capable of covering practically all test and qualification needs for domestic air conditioning system, both split and monoblock, either functioning exclusively as air conditioners or also as heat pumps.

Two models are available, making it possible to work on conditioners of a maximum capacity of 12kW and 20kW, respectively. Tests can be conducted in accordance with EC standard ISO 5151-2010, keeping in mind that it is very similar to the equivalent standards used in other industrial areas.

Two models are available, making it possible to work on conditioners of a maximum capacity of 12kW and 20kW, respectively. Tests can be conducted in accordance with EC standard ISO 5151-2010, keeping in mind that it is very similar to the equivalent standards used in other industrial areas.

The calorimeters come complete with a software package, the product of years of experience in the field, which simplified the running of the tests and provides an immediate reading of the significant parameters. The software, in addition to processing the data to permit an immediate display of the test progress, produces a report summarizing the results attained and stating the characteristics of the tested conditioner.

Main features:

| Model | CAL12PS | CAL20PS |

| Air Conditioner Thermal Power (kW) | 12 | 20 |

| Overall dim. (mm) | 8900 x 3300 x 3160 H | 12200 x 4100 x 3460 H |

| Indoor and Outdoor Rooms dim. (mm) | 3700 x 3000 x 2400 H | 5350 x 3800 x 2700 H |

| Indoor Temp. Range (°C) | +10 to +40 | +10 to +40 |

| Outdoor Temp Range (°C) | -20 to +60 | -20 to +60 |

| Indoor Dewpoint Range (°C) | +5 to +39 | +5 to +39 |

| Outdoor Dewpoint Range (°C) | +5 to +59 | +5 to +59 |

| Max Steam Flow (Kg/h) | 25 | 25 |

| Code Tester Air Flow (m³/h) | 4000 | 4000 |

| Condensation | water condenser | water condenser |

| Refrigerant | R404A | R404A |

| Absorbed Power (kW) | 115 | 155 |

The basic configuration includes:

- no. 4 portholes for cables entry

- no. 2 windows (mm 450 x 450)

- no. 2 inside power plugs

- PC and WinKratos control software

- Code tester sensors

- Thermal efficiency calculus

Control system overview

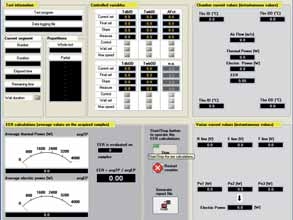

WinKratos is the software developed by Angelantoni Test Technologies for the monitoring and supervision of climatic chambers and environmental testing systems. The extremely flexible and powerful structure of this package has been further perfected to afford complete integration and effectiveness of use with the calorimeter.

The machine and its functions are managed and monitored by means if a Siemens S7 controller. This controller is responsible for acquiring the chamber status (chamber measurements, DUT electrical parameters, alarms and events), for executing the tests as requested by the operator, and for the safety of the machine itself.

** the air treatment system is to big to be installed inside the chamber

The interface of the control system with the outside and therefore with the operator, takes place through two different HMI interface levels. The first is a small operating panel positioned on one of the sides of the chamber, and the second is the WinKratos software. Many of the functions are shared by both, and both are based on the same operating philosophy so that they will be homogeneous. But each has specific characteristics depending on the operating field to which it refers.

The operating panels permits the low-level configuration of many operating functions and characteristics of the chamber, the setting and changing of basic parameters, and the possibility to calibrate all the measurement channels. The various functions are subject to different password levels, making it possible to select the personnel authorized for the various operations. The WinKratos software is the advanced supervision and monitoring environment normally used for managing the system.

Through WinKratos it is possible to create tests profiles (programs), launch or interrupt the execution of a test in manual or program mode, display data in table or graphic form, and generate a report showing test results. Particular attention has been paid to the immediacy, simplicity and operating effectiveness of the interface with which the operator will be working. All functions are highly intuitive, and appropriate messages and interlock conditions on the actions performed ensure error-free tests.

Personalized solutions

The measurement of the performance of a domestic air conditioner must be carried out in accordance with the regulations of the country where the conditioner is to operate. Almost all regulations envisage several methods of energy efficiency measurement, which are often very different from one another. Therefore, there are many types of calorimeters, each closer to one method than to another and characterized by specific construction solutions.

Calorimeters for domestic air conditioning systems can also be classified according to the power range to be measure, and each category is suitable for a specific performance range.

Calorimeters for domestic air conditioning systems can also be classified according to the power range to be measure, and each category is suitable for a specific performance range.

Angelantoni Test Technologies have been operating in this sector for many years producing numerous types of calorimeters for domestic air conditioning, from those developed in compliance with the requirements of international standards to highly-customized models, capable of assessing the performance and efficiency of the most varied air conditioning systems.

Automotive field

The calorimeters for measuring the efficiency of automobile air conditioners make up another, very particular category. Automobile air conditioners, characterized by geometries which depend on the car on which they are installed, very often require a calorimeter that is specifically designed and therefore highly customized. In some cases automobile manufacturers also ask for the possibility to simulate the extreme transient operating conditions to which conditioners are subjected.

The vast experience and know-how Angelantoni have acquired enable them to meet these complex needs and produce test benches which are in strict compliance with the existing standards and regulation, up to prototype equipment for cutting-edge experimentation.