EURAC - INSTITUTE FOR RENEWABLE ENERGY CASE HISTORY

Starting with the concept of the Hotbox (in accordance to the UNI ISO 12567-1 Standard), EURAC embarked on a project to design and implement a new facility for the testing of elements including both passive (Insulation, Cladding and shadowing Systems) and active (ST collectors, PV panels etc) components used in the construction Industry.

Starting with the concept of the Hotbox (in accordance to the UNI ISO 12567-1 Standard), EURAC embarked on a project to design and implement a new facility for the testing of elements including both passive (Insulation, Cladding and shadowing Systems) and active (ST collectors, PV panels etc) components used in the construction Industry.

The main objective of this laboratory is to investigate and therefore to give support for the development of multi-functional building components, allowing to increase the envelope and whole building energy efficiency, through a better passive and active control of energy fluxes, towards the so called Net Zero Energy Building.

Facility Overview

Angelantoni Industries, the world's leading supplier of specialised thermal chambers were selected to design and build the main facility based on their previous experience in manufacturing and producing complex solutions for this type of requirement.

Angelantoni Industries, the world's leading supplier of specialised thermal chambers were selected to design and build the main facility based on their previous experience in manufacturing and producing complex solutions for this type of requirement.

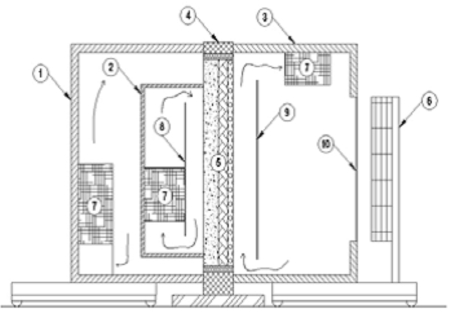

The main facility consists of three climatic chambers:

- The cold chamber

- The metering chamber

- The guard chamber

The cold chamber emulates the outdoor environment, while the metering one emulates the indoor environment. The metering chamber is surrounded by a guard chamber held at the same temperature of the metering one with a maximum difference of ±0.2°C in order to minimize the thermal flux between them. The temperature within the metering chamber is controlled by a refined power regulator. The cold chamber covers a temperature range of -20°C to 40°C, while the metering chamber covers a temperature range of 18°C to 40°C, with a temperature fluctuation in time less than ±0.1°C. The chamber also allows the simulation of the ventilation occurring on the surface of the tested assembly or components by means of controlled fans. The force-air ventilation is vertical, from the roof to the floor in the metering chamber and from the floor to the roof in the cold chamber. Along the surface of the specimen on both sides, with a speed range of 0.1 to 10 m/s in the cold chamber and less than 0.3 m/s in the metering one.

The velocity fluctuation in time is less than ±10.025 m/s. The guarded hot-box is also provided with a humidity-control system in order to avoid condensation and moisture transport within porous samples that could strongly effect the evaluation of its energy performances.

For the cold chamber, the relative humidity range is of 40-80%, while in the metering chamber a dehumidifier is in the charge of keeping the percentage under 15%. The guarded hot-box is able to test several kinds of samples both opaque and complex components. The samples can have a maximum dimension of 3m x 3m and a thickness until 50cm, however the measurements will always be done over an area of 2.42m x 1.92m that corresponds to the aperture of the metering chamber. Type T thermocouples are mounted inside the cold and the metering chambers these thermocouples measure the temperature of the air and the specimen surfaces in order to evaluate the thermal performances of the studied wall assembly. Within each of these two chambers a relative-humidity sensor and an anemometer are installed to control their climatic conditions.

Electrically Isolated Test Enclosure

A hydraulic close loop test system together with an artificial sun simulator allows the facility to evaluate the energy efficiency of active solar systems integrated into the envelope and therefore the thermal behavior of the overall construction components. The sun simulator will be set up outside the cold chamber and its irradiation beam will reach the target passing through a transparent aperture on the back side of the cold chamber.

The sun simulator set to irradiate a 3m2 area (1.5 x 2.0 m) with a maximum irradiance of 1000w/m, the sun simulator can be dimmed to its 70% of its full capacity. It will therefore be possible to investigate and to better understand the interaction between buildings passive and active components under steady-state and dynamic conditions both for the different elements (eg thermal bridge as well as temperature increasing of the solar cells due to the PV integration) can also be studied.

Conclusion

The new 2010/31/EU directive on the energy performance of buildings is promoting buildings with a good balance between energy consumed and produced. To achieve such goals multi functional and high-performance building envelopes as well as building components integrating active solar systems are being developed. The further goal of the test facility is to promote synergies between manufacturers of engineered walls, suppliers of photovoltaic (PV) modules and solar thermal collectors and to supply them with an effective instrument of pre-commercial systems, thus facilitating a fast development of integrated energy-producing buildings walls.

Future Trends

This innovative facility will be at the forefront of on determining the future trends in other key areas and it is expected that the International interest from both researchers and Industry suppliers will increase to further investigate and develop this testing methodology

Key new areas that will benefit from this type of research will include the following:

- Suppliers of New Materials (PCM, VIP thin and dynamic insulation etc.)

- New technologies for devices used in Ventilation and energy delivering devices in the facades

- Development of Multifunctional and innovative components for the envelope

Angelantoni Industries - Environmental Testing Business Unit

Since 1952 and under the ACS brand, Angelantoni Industries has introduced world-wide environmental test chambers for all types of tests on materials, components and finished products. ACS brand has always been associated with vast experience and flexibity in customized solutions, with undisputed expertise in technologies, gained also through tight cooperation with research institutions, universities and industrial partners.

- Guard chamber

- Metering chamber

- Cold chamber

- Fixed sample frame

- Wall samples

- Sun simulator

- Air conditioning devices

- Opaque panel to control air flux

- Transparent panel to control air flux

- Tempered glass